Water Jet Cutting Software Autodesk

The Trim-Jet tm 'P' water-jet edge-trimming system is indispensable for most modern paper machines of all grades. Jet-X™ 2000 The Jet-X tm 2000 is an automated, single cut water-jet tail cutter with precise tail positioning capability.

The History of Waterjet Cutting

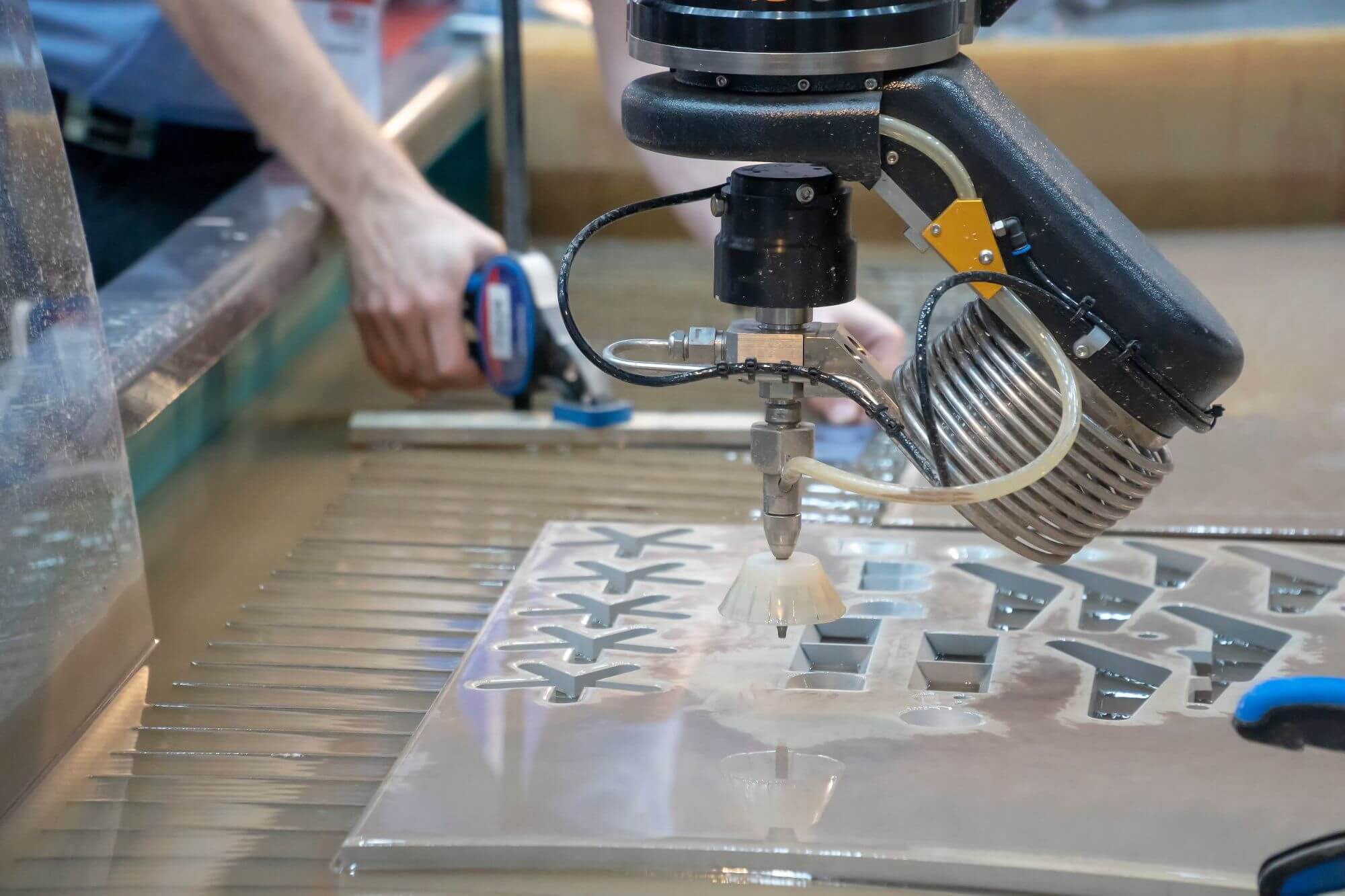

UHP water cutting, also known as waterjet or water jets, is a high-energy (380MPa) water flow generated by multi-stage pressurization of ordinary water. This water is then expelled at a speed of nearly 1,000 meters per second through a highly precise ruby nozzle (Φ0.1-0.35mm), making it a highly efficient cutting method.

waterjet cutting The Upstyle Wood Guide

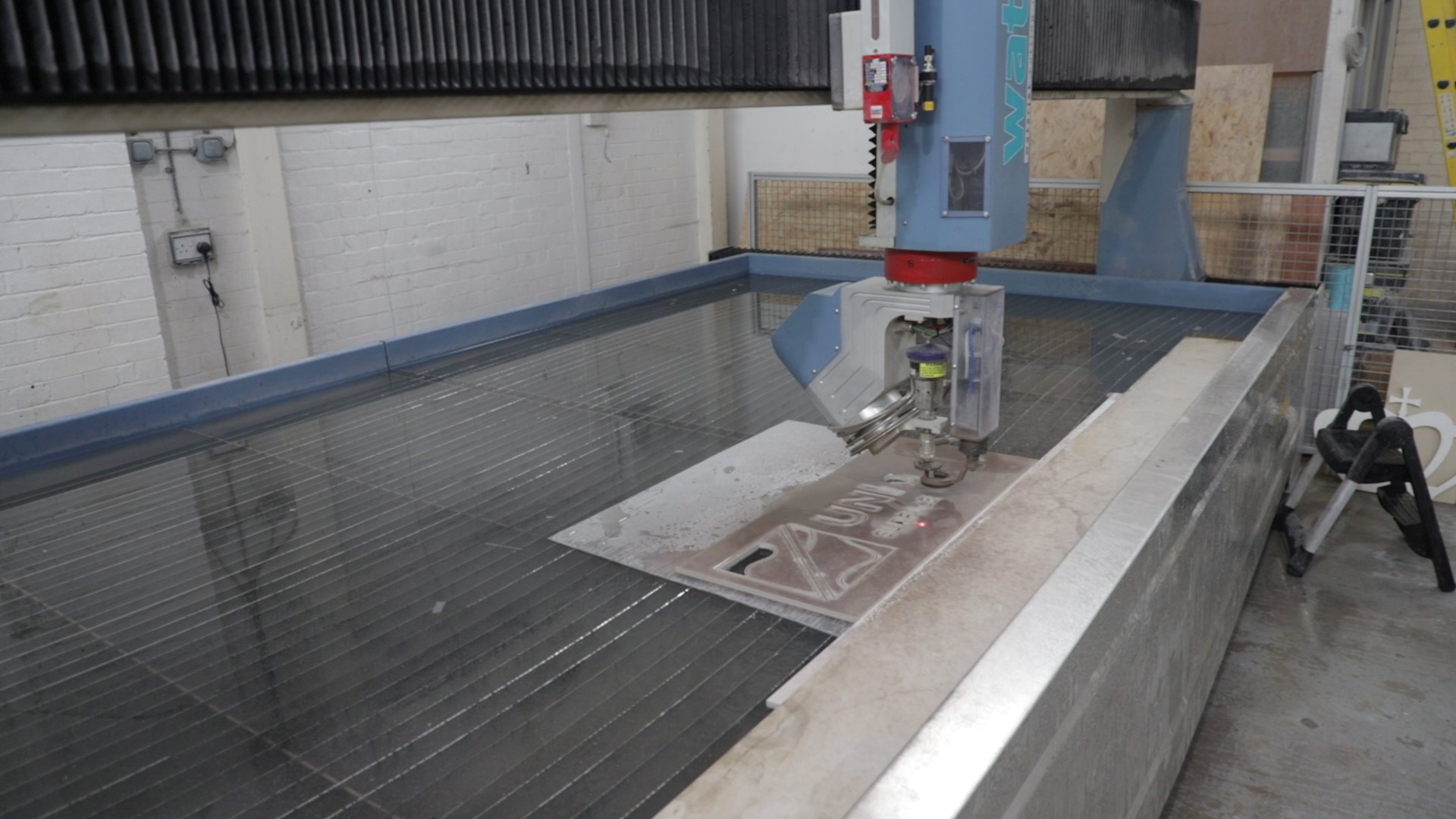

Waterjet cutting technology is one of the fastest growing major machine tool processes in the world. There are virtually no limits to what waterjets can cut, which is why companies of all kinds and sizes are realizing greater eficiencies and productivity by implementing waterjets in their operations. Waterjet Basics

G3 Machining Waterjet Cutting

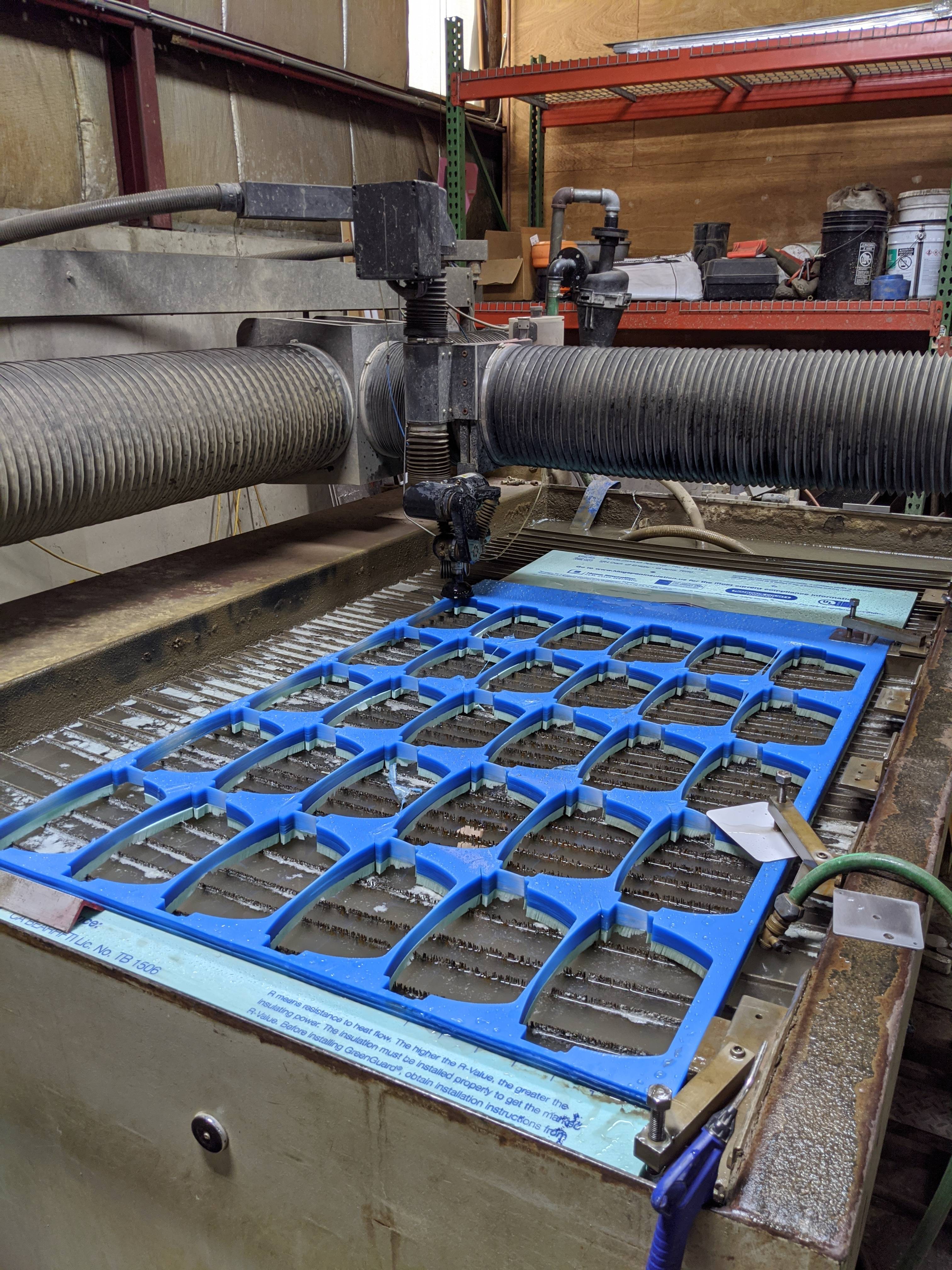

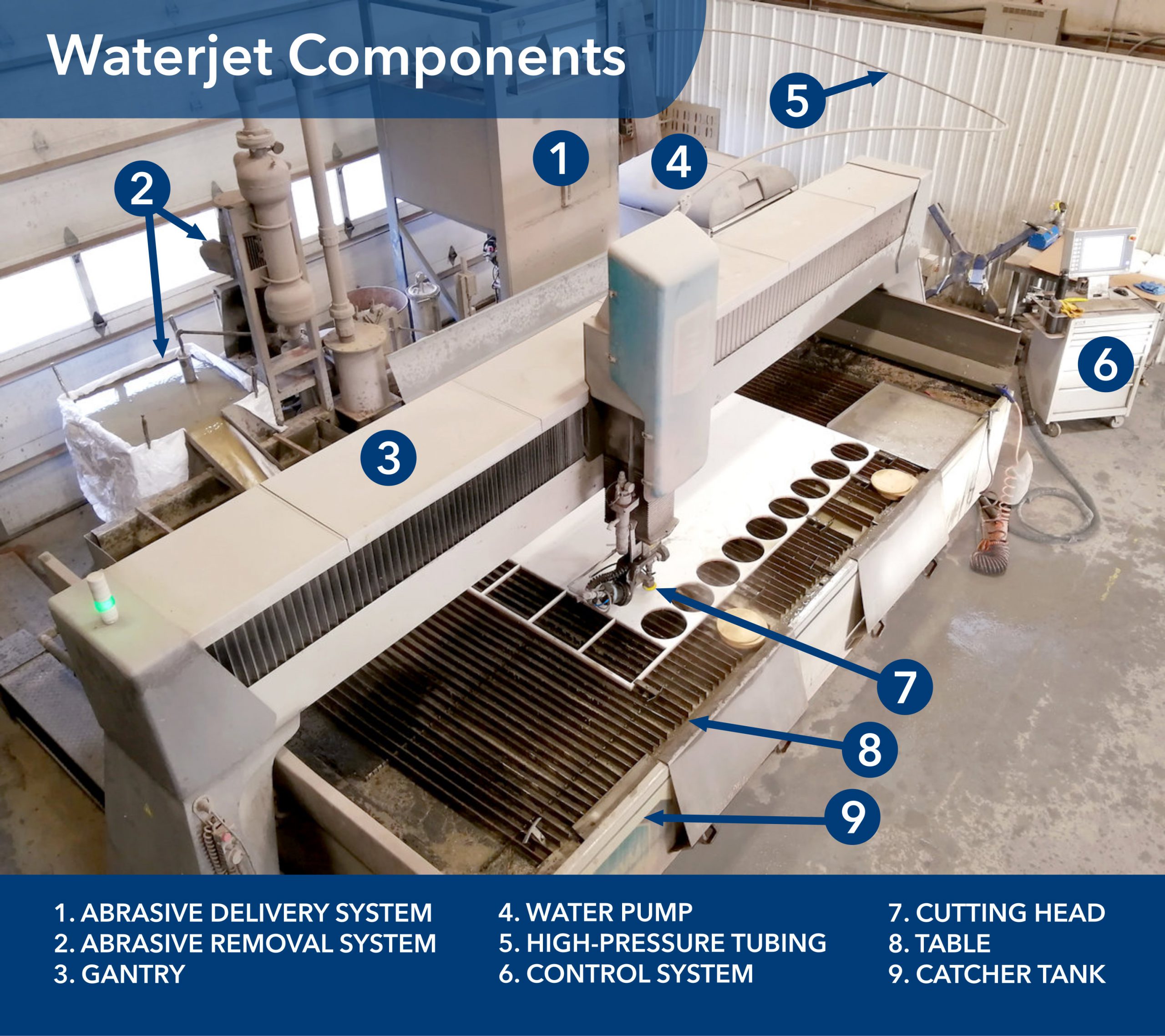

WHAT IS A WATERJET? A waterjet utilizes a high pressure stream of water to erode a narrow line in the stock material. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting.

Description of a Waterjet Cutting System A Technical Guide to

Water-jet cutting can be used on almost all paper grades and weights. As an example, some systems have been installed on tissue machines with weights below 10 gsm and at the other end on packaging grades over 1300 gsm.

Waterjet Cutting Near Me East Valley Precision

Endnotes Waterjet cutting technology is one of the most common methods whose applications you can find in a lot of different structures- from high-quality kitchen marble tops to industrial tools and processes. If you look at the equipment that makes waterjet cutting possible, it looks very sophisticated and high-end.

Waterjet Cutting Process, Benefits and Materials Explained Fractory

1. Can You Cut Paper With a Water Jet Cutter? 2. What are the Benefits of Using a Water Jet to Cut Paper? 3. Applications of Waterjet Cutting Paper 4. Tips For Cutting Paper With a Water Jet Paper Cutter 5. Factors to Consider When Choosing a Water Jet Paper Cutter 6. Conclusion Cutting paper might seem like an easy job.

The Advantages of Water Jet Cutting Imc Press

Why VICHOR's Waterjet Cutting Paper Machine is the Best Choice for SMB Owners. As a small or medium-sized business owner, VICHOR's waterjet cutting machine is an ideal choice for your paper cutting needs. Its efficiency, precision, and versatility will enable you to deliver a wide range of high-quality products to your customers, thereby.

Water Jet Cutting Norwood Medical

Waterjet cutting was pioneered in the 1930s as a method for measuring and cutting reams of paper, but it has come a long way since then. Nowadays, waterjet cutting is used in various industries and even found its way into the art world. But what exactly is a waterjet cutter, and how does it work?

Waterjet Cutting Edmonton Advantage Manufacturing

Waterjet slitting systems are the fastest, most efficient way to cut paper products. Cut dust free, significantly improving work conditions, safety, and product quality; Eliminate rewinding - a slitter can be installed directly on the machine and the edge meets all requirements for converting operations; Higher cutting speeds

The Advantages and Disadvantages of Waterjet Cutting Ballard Machine

Waterjet cutting with pure water is the ideal solution for the cutting and slitting of paper and plastic webs as well as cardboard panels. The technology is already widely used in the production of wallpaper and packaging material.

WHAT IS WATERJET CUTTING? Waterjet

Pure Waterjet Cutting: Pure waterjet cutting can be used to cut soft materials like food items, paper, foam, rubber, felt, and soft plastics. Abrasive Waterjet Cutting: Abrasive waterjets can be used to cut virtually any material you can think of: carbon fiber, metals, hard plastics, ceramics, stone, glass, wood, earth, etc. Speed

Water jet cutting Ridderflex

Water-jet cutting is a nonconventional machining method that makes use of high-pressure water jets with (i.e., abrasive water-jet cutting) or without (i.e., plain water-jet cutting) fine abrasive particles to virtually cut any kind of materials into two- or three-dimensional shapes, provided that the machine has the capability of ultrahigh-pressure pump (UHP) and the flexibility of positional.

Water Jet Cutting Paper The best paper processing tools

Flow is the inventor and world leader in waterjet cutting solutions. With waterjet, you've got the versatility to cut any material, any shape, and any size.. Paper. Precision. Bevels. Waterjet in the Real World. The flexibility of waterjet means it nests perfectly into a wide variety of industries. Explore some of the industries where.

Custom Water Jet Cutting. We will cut whatever you imagine.

Key Benefits to Cutting Paper with Waterjet Cut dust free 24 hour a day operation with redundant systems Improved working conditions Eliminate rewinding by slitting paper on-line Strong cut edges Clean cuts Minimal kerf Put Flow's Waterjet to the Test Your Part, Your Specs, Our Waterjet. Get a Test Cut

Water Jet Cutting Abraj Trading

cut material A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance.